Kasaragod: As Kerala battles COVID-19 on war footing, a physics professor at the Kasaragod government college has developed a novel, low-cost, portable equipment for respiratory support.

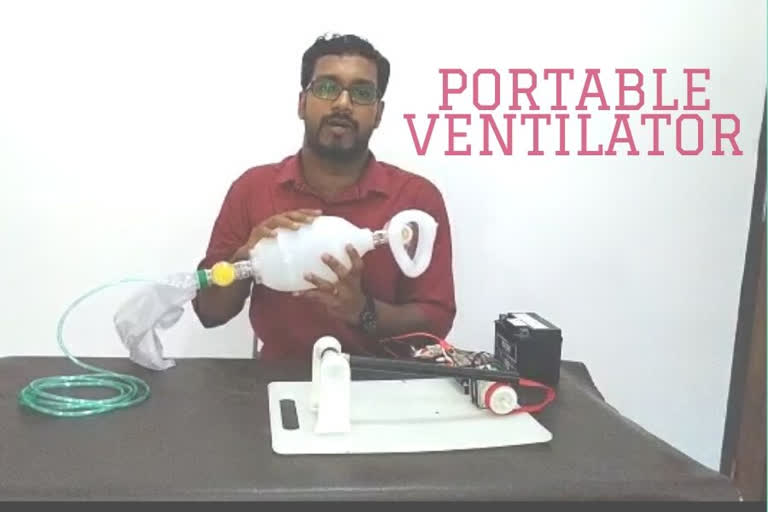

According to reports, Dr. A V Pradeep, a native of Payyanur, Kannur developed a portable ventilator, which operates with a silicon-made AMBU (Artificial Manual Breathing Unit) bag referred to as manual resuscitator.

The innovation is of huge significance as for the elderly and the vulnerable population, especially those with co-morbid 'conditions' such as heart diseases or Type 2 Diabetes, COVID-19 can be life-threatening unless ventilator assistance is provided.

Speaking to ETV Bharat, Dr. Pradeep explained various aspects of the AMBU bag, oxygen reservoir and the automated aspects of the portable ventilator- DC electric motor, microcontroller and a motor controller.

Read: COVID-19: Know all about manufacturing and availability of PPE kits, N95 masks & ventilators

The ventilator is based on a controlled operation which supplies the required volume of air to the patient. The speed and time of the oxygen inflow can be regulated with the help of the stepper motor. A 12-volt battery is required to operate the Arduino, the microcontroller.

"COVID-19 affects the respiratory functions of a person. There are reports from across the world over the unavailability of ventilators leading to multiple deaths. In order to prevent such as situation in Kerala, I tried to develop a manual respiratory support system," Pradeep said.

Pradeep further claimed that this ventilator can be readied at the cost of just Rs 3000. The most sophisticated computer-controlled ventilators cost around Rs. 40 lakh while more modest foreign-made ones cost around Rs. 15 lakh with Indian-made ventilators costing around Rs. 6 lakh.

It is estimated that there are around 40,000 ventilators in India at present, mostly in the private hospitals. The Indian industry has a maximum manufacturing capacity of approximately 6,000 units per month, but even the Indian-made devices use a lot of foreign-made parts whose availability would now be uncertain, when every country would be maximizing their own ventilator production.