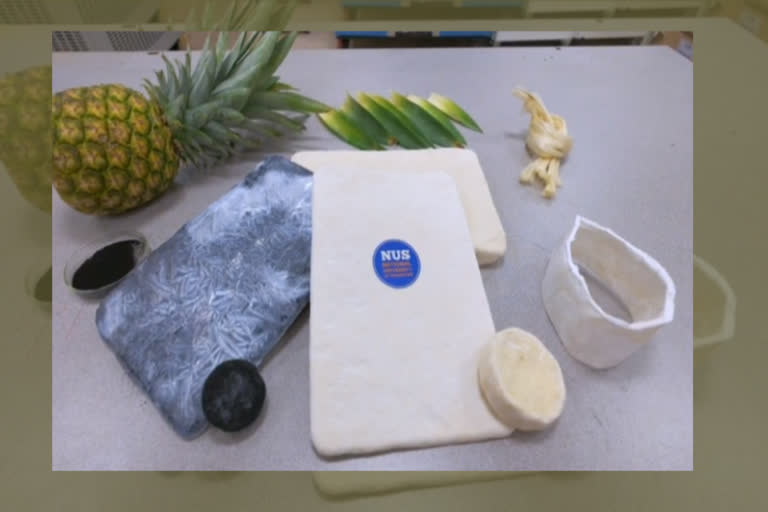

Singapore: Researchers from the National University of Singapore (NUS) have devised a simple and low-cost method of using pineapple leaf fibres to make ultra-light, biodegradable aerogels.

“These eco-aerogels made up of pineapple leaf fibres are very versatile. They are effective as oil absorbents and for heat and sound insulation. We’ve also demonstrated their potential applications in food preservation and wastewater treatment. This is a big step towards sustainable agriculture and waste management, and provides a further source of income for farmers,” Duong Hai-Minh, an associate professor at NUS said.

- Eco-aerogels can be created easily, and this leads to a low production cost—for example, it costs less than S$10 to create a sheet of aerogel that measures 1 m2 in area and 1 cm in thickness. When an aerogel sheet of the same size reaches the market, it can be sold at a price range of S$30 to S$50.

- The fabrication procedure differs based on the type of raw material employed. The major steps involve blending/shredding, combining with water and a trace quantity of safe chemicals, stirring, ageing, freezing, and finally freeze-drying.

- Around 12 hours is needed on average to create aerogels from the raw materials—this is approximately 18 times faster when compared to the traditional “sol-gel” technique used for producing commercial aerogels.

- To make sure that eco-aerogels perform the role of food preservation, they are altered with activated carbon powder to allow them to effectively absorb ethylene gas, also called the “fruit-ripening hormone.” This gas starts the ripening process in vegetables and fruits.

- This is particularly pertinent to climacteric vegetables and fruits—such as tomato, potato, papaya, mango, and banana—that continue to ripen significantly after harvest.

Vast quantities of fresh agricultural produce are discarded due to inadequate post-harvest storage and processing facilities, as well as inefficient or disrupted transportation systems. Therefore, cutting down spoilage can go a long way in reducing waste. In our lab experiments, eco-aerogels modified with activated carbon can delay the rotting process by at least 14 days.

Prof Phan-Thien said, “The modified eco-aerogel can absorb six times more ethylene than commercial potassium permanganate ethylene absorbents. This is also a safer method compared to the conventional use of strong oxidising agents, and more efficient than non-toxic chemical sprays, for food preservation.”

- Eco-aerogels produced from the fibres of pineapple leaves have more robust mechanical characteristics and can also be used in wastewater treatment.

- When eco-aerogels are coated with a chemical known as diethylenetriamine (DETA), they are capable of removing four times more nickel ions in industrial wastewater, when compared to traditional techniques using synthetically doped graphene and naturally derived clay.

- By adopting different types of chemical coatings, the eco-aerogels can be used to extract different kinds of heavy metals from aqueous solutions.

Due to its high porosity, eco-aerogels are highly efficient in removing metal ions, even in dilute solutions where the amount of metal ions is low. The treatment process is simple, cheaper and does not generate secondary waste. Eco-aerogels can also easily desorb the metal ions and be reused several times, further reducing costs.

The research team, comprising nine members from NUS, has now filed a patent for producing the eco-aerogels made from pineapple leaf fibres for wastewater treatment and food preservation. The team is now planning to work with an industry association to scale up and market this new technology.

Based on their potential outcomes, the team is currently seeking to expand their studies in several major domains.

Firstly, the researchers are identifying different kinds of chemical coatings to produce eco-aerogels that exhibit high and selective adsorption of varied heavy metal ions. Secondly, they are looking at how to efficiently recover heavy metals from the eco-aerogels following wastewater treatment, in addition to reusing the eco-aerogels.

Lastly, the researchers are performing research works to create sophisticated, economical non-woven methods to fabricate eco-aerogels constantly as a roll with infinite length. Non-woven methods eliminate the need for solvents and could create eco-aerogels more quickly, using cheaper equipment and less energy. Such an approach will considerably decrease the production cost relating to eco-aerogels.

Also Read: Virginia researchers studying 'the sound of plants dancing' to improve agriculture