AMES, Iowa: Researchers of Iowa State have developed ways to check the freshness of the fish and meat which you are consuming. They dipped their new, printed sensors(with high-resolution aerosol jet printers on a flexible polymer film) into tuna broth and watched the readings.This study has been published online by the journal 2D Materials, supported by The National Science Foundation, the U.S. Department of Agriculture, the Air Force Research Laboratory and the National Institute of Standards and Technology

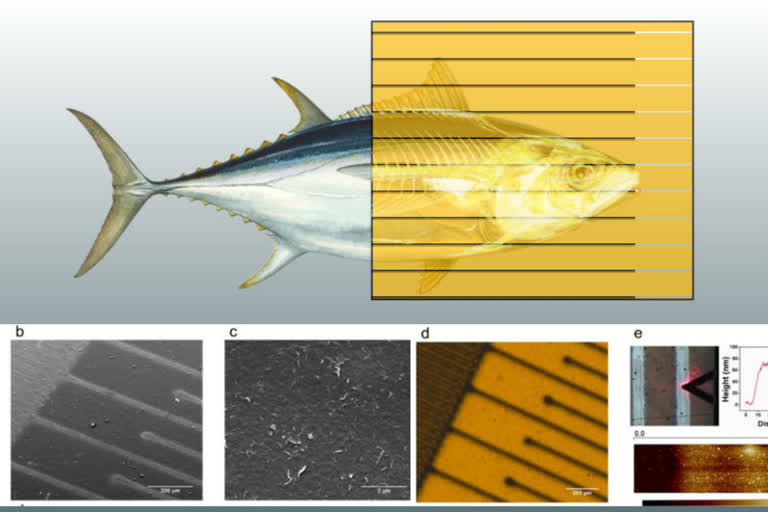

How these electro-chemical sensors work? Graphene, a super material made of carbon honeycomb, known for its strength, electrical conductivity, flexibility and bio-compatibility is a part of sensor technology which helps to detect histamine via the creation of high resolution electrodes. Histamine is an allergen and indicator of spoiled fish and meat.

This technology can can detect histamine down to 3.41 parts per million.

The U.S. Food and Drug Administration has set histamine guidelines of 50 parts per million in fish, making the sensors more than sensitive enough to track food freshness and safety.

"This fine resolution is important," said Jonathan Claussen, an associate professor of mechanical engineering at Iowa State University and one of the leaders of the research project. "The closer we can print these electrode fingers, in general, the higher the sensitivity of these biosensors."